中文

Русский

español

Production process

Need Promotional Custom Tote Bags?

You Can Print Your Company Logo on any of our Bags

Printing process

What kind of printing process will work best for our customized bags? Today, we will learn about several common printing processes for bags to see which one is best for us.

Screen Print

Recommended for multiple colors, solid designs, company logos, writings. Minimum 24 pcs

View More

Digital Print (DTG)

Recommended for unlimited colors, watercolor paints, pictures, detailed artworks. No Minimum.

View More

Embroidery

Recommended for up to monograms, company logos, writings and artworks. Minimum 12 pcs.

View More

All Over Printing

Recommended for unlimited colors, watercolor paints, patterns, it can be printed all over the bag.

View More

Custom tote bags

Design tote bags that get your brand seen well after an event. Personalized tote bags are a go-to favorite for event giveaways and promotional packs. They're a great alternative to plastic bags – ideal for grocery shopping, running errands and more.

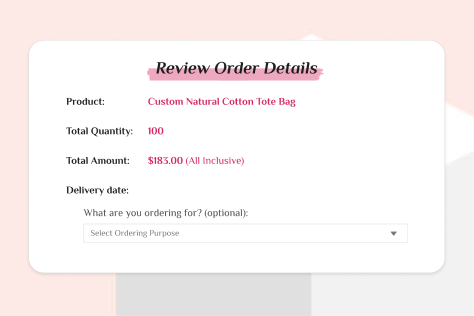

Canvas bag custom process

We understand that each customer has unique requirements and preferences. With our OEM services, we provide tailored solutions that meet the specific needs of our clients. From design customization to product development, we ensure that our customers receive products that align with their vision.

1

Browse Designs

Explore our collection of stylish canvas bags and choose your preferred design.

Customize Options

Select colors, patterns, and personalization details to create a unique bag.

2

3

Place Order

Add your customized bag to the cart and proceed to checkout.

Production & Quality Check

Our team crafts your bag with care and conducts a thorough quality check.

4

5

Delivery

Sit back and wait for your personalized canvas bag to be delivered to you.

Get a Quote

Metal Finishing Library

Polished Chrome

Hardware Color

Stain Chrome (Matte)

Hardware Color

Stain Gun Metal (Matte)

Hardware Color

Polished Brass (Light Gold)

Hardware Color

Stain Brass (Matte)

Hardware Color

Brass

Hardware Color

Antique Gun Metal

Hardware Color

Coming Soon

Hardware Color

Precision Moulding

Metal Injection Moulding

Metal Injection Molding technology is a set of interpenetrating advanced technologies that combine 'injection molding', 'polymer chemistry', 'powder metallurgy' and 'metal material science'. Under the general trend of seeking quickness and innovation, this technology quickly and accurately transforms the design into functionality, and can be applied for mass production, eliminating tedious machining procedures.

Compared with traditional processes, this technology has the advantages of manufacturing high-density, high-precision, high-strength, uniform organization, excellent performance, and low production cost. With the continuous improvement of Gahumi technical team and customization requirements, it has become the mainstream technology for the manufacture of metal parts in fashion industry.

Compared with traditional processes, this technology has the advantages of manufacturing high-density, high-precision, high-strength, uniform organization, excellent performance, and low production cost. With the continuous improvement of Gahumi technical team and customization requirements, it has become the mainstream technology for the manufacture of metal parts in fashion industry.

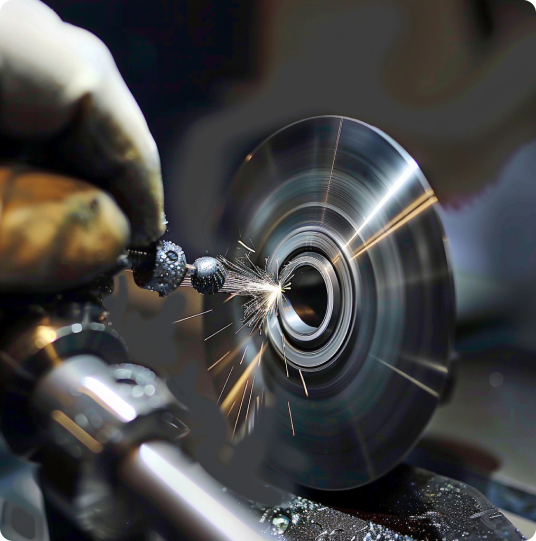

Precision machining

Precision machining applications include a large and comprehensive CNC machine tools and machining centers, including lathes, milling machines, drilling machines, grinders, wire cutting, electric sparks, laser technology, etc.,

The process is a high-precision machining process in which the size of the workpiece is changed by the machine in accordance with the product design and specification requirements, and it will not cause material quality changes or chemical reactions at room temperature.

This multi-oriented and multi-performance flexible processing method is not only suitable for diverse small-scale production in fashion industries, but also very suitable for large-scale production operations.

The process is a high-precision machining process in which the size of the workpiece is changed by the machine in accordance with the product design and specification requirements, and it will not cause material quality changes or chemical reactions at room temperature.

This multi-oriented and multi-performance flexible processing method is not only suitable for diverse small-scale production in fashion industries, but also very suitable for large-scale production operations.

Precision forging

Precision casting technology is an advanced technology with near net shape forming. This casting is suitable for large and small workpieces, and more suitable for products with three-dimensional and special-shaped designs that cannot be formed by molds. In addition to linear tolerances, parts can also achieve higher geometric tolerances.

With the continuous improvement of Gahumi's technical team, the integration of vacuum technology has made the surface roughness of the blank produced by precision casting smaller and smaller, which greatly saves the workload of surface treatment after traditional casting technology, and is more suitable for the rapid production needs of fashion industries.

With the continuous improvement of Gahumi's technical team, the integration of vacuum technology has made the surface roughness of the blank produced by precision casting smaller and smaller, which greatly saves the workload of surface treatment after traditional casting technology, and is more suitable for the rapid production needs of fashion industries.

Surface Treatment

Metalworking Polishing

Based on the high standards for product appearance and high-precision requirements of European fashion industries, Gahumi supplier combined scientific analvsis methods to create a unique metalworking polishing system that includes "three-dimensional grinding", "precision plane grinding", "high-frequency vibration grinding" "fine metalworking technology" and "plasma technology". In accordance with diverse specifications and material characteristics, this technology can give products a standardized special processing process, which not only stabilizes the quality of the polishing process, but also meets the standards of flexible production management of diversified products. This unique technical application has industrialized metalworking techniques, and implemented the spirit of ingenuity, becoming one of the core technologies of Gahumi hardware chain.

PVD

Physical vapor deposition (PVD) technology is a surface treatment technology that deposits thin firms by a physical mechanism, has eco-friendly process without heavy metals or chemical pollution and the quality is stable.

With the continuous optimization of the technical teams, we have made customized hardware that meet the needs of European fashion industry, and the high-quality results beyond the traditional electroplating technology with comprehensive advantages such as wear resistance, oxidation resistance, corrosion resistance, antibacterial, etc.. As the core surface treatment technolog, it can provide high-end brand products with precious metal appearance coating at the highest standard.

With the continuous optimization of the technical teams, we have made customized hardware that meet the needs of European fashion industry, and the high-quality results beyond the traditional electroplating technology with comprehensive advantages such as wear resistance, oxidation resistance, corrosion resistance, antibacterial, etc.. As the core surface treatment technolog, it can provide high-end brand products with precious metal appearance coating at the highest standard.

Frequently asked questions

We provide three different solutions according to the various order

requirements. Different services are provided for customers to selected.

requirements. Different services are provided for customers to selected.

MOQ for wholesale custom canvas bags is X units, ensuring cost-effectiveness.

MOQ for wholesale custom canvas bags is X units, ensuring cost-effectiveness.

MOQ for wholesale custom canvas bags is X units, ensuring cost-effectiveness.

MOQ for wholesale custom canvas bags is X units, ensuring cost-effectiveness.

MOQ for wholesale custom canvas bags is X units, ensuring cost-effectiveness.

MOQ for wholesale custom canvas bags is X units, ensuring cost-effectiveness.

View More

To Get Your Fabric-Printing Products Customize Sample Catalog

Choose our one-stop Fabric-Printing Products solutions to drive growth and profitability for your business.

One-to-one consultation service

Quick response within 1 hour

Custom Fabric-Printing Products experts with 31-years experience

OEM or ODM Custom services

Minimum order quantity 300 pieces

Fill out the form

Industry Applications

About us

Follow me

© 2024 Guangdong Gahumi Textile Co., Ltd | Powered by

Matchpages

Tote Bags

Tote Bags

hot Hat

hot Hat